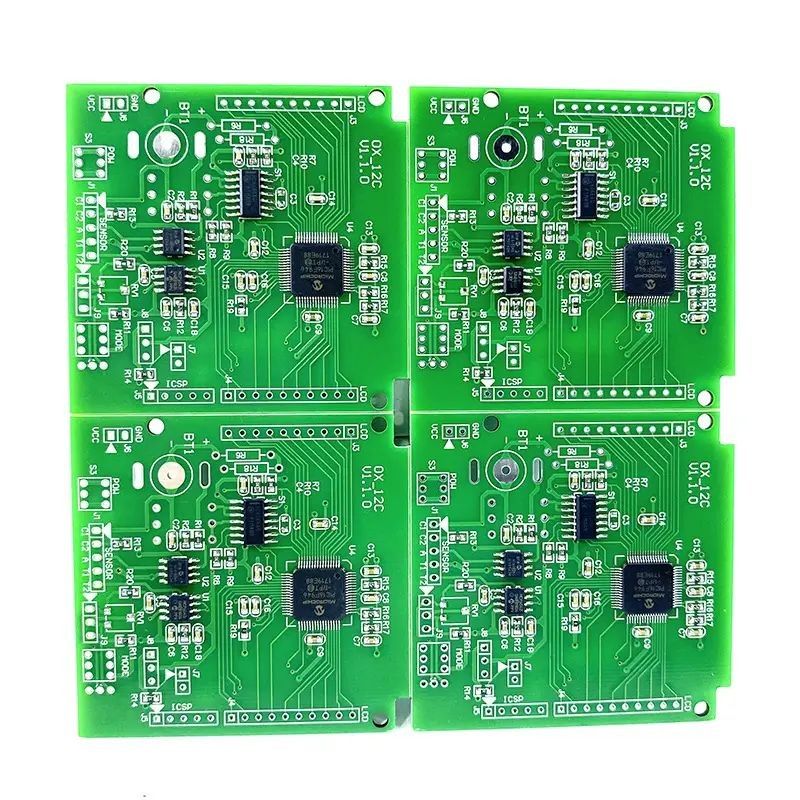

PCB Manufacture Gerber PCBA Assembled Flexible PCB Board Blender Motor Double sided PCB.

| Description |

Capability |

|

Testing Service

|

AOI X-Ray Function Test

|

|

Keywords

|

PCBA OEM PCB Assembly

|

|

Material

|

FR4 /aluminum/ceramic CEM1

|

PCB Manufacture Gerber refers to the process of fabricating a printed circuit board (PCB) based on the Gerber files, which contain the design information for the PCB layout. In the case of a double-sided flexible PCB board for a blender motor, the PCB is designed to accommodate the specific requirements of the blender motor and its associated circuitry. Here's a description of the key aspects of manufacturing a double-sided flexible PCB for a blender motor:

PCB Design and Gerber Files: The PCB design process involves creating the layout of the PCB using specialized software. The design includes the placement of components, routing of traces, and any necessary flex areas for the flexible PCB. Once the design is complete, the Gerber files are generated. These files contain the information required by the PCB manufacturer to fabricate the PCB accurately.

Material Selection for Flexible PCB: For a flexible PCB, the choice of materials is crucial. The selection typically includes a flexible substrate material, such as polymerize (PI), which offers excellent flexibility and heat resistance. The thickness and other specifications of the flexible material are determined based on the specific requirements of the blender motor and the desired mechanical properties of the PCB.

PCB Fabrication: The fabrication process begins by preparing the flexible substrate material. This involves cutting the material to the required dimensions and applying an adhesive layer if necessary. The next step is to apply a conductive layer, usually copper, to both sides of the flexible substrate. This is done through processes like electroless copper plating or sputtering.

Solder Mask and Silkscreen: To protect the PCB and provide insulation, a solder mask is applied to both sides of the PCB. The solder mask covers the exposed copper traces, leaving only the desired areas for component soldering. A silkscreen layer is also added, which includes labels, component designation, and other markings to aid in assembly and identification.

Component Assembly and Soldering: Once the PCB is fabricated, the next step is to assemble the components onto the PCB. This involves placing the components in their designated locations and soldering them onto the PCB using appropriate methods such as reflow soldering or wave soldering. The component assembly process ensures the proper electrical and mechanical connections between the components and the PCB.

Manufacturing a double-sided flexible PCB for a blender motor involves designing the PCB layout, generating Gerber files, selecting suitable materials, fabricating the PCB, applying solder mask and silkscreen, assembling the components, and conducting testing and quality control checks. The aim is to produce a high-quality, reliable PCB that meets the specific requirements of the blender motor and ensures efficient and safe operation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!