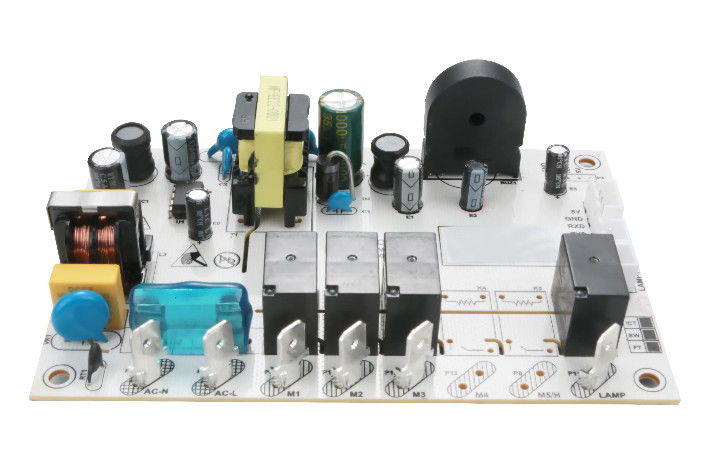

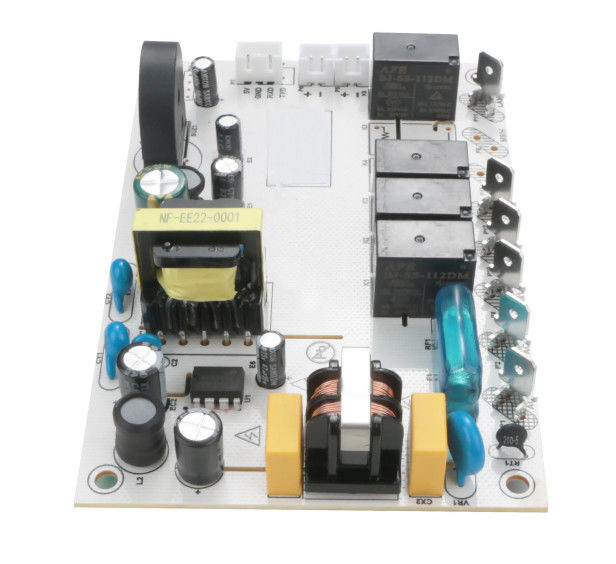

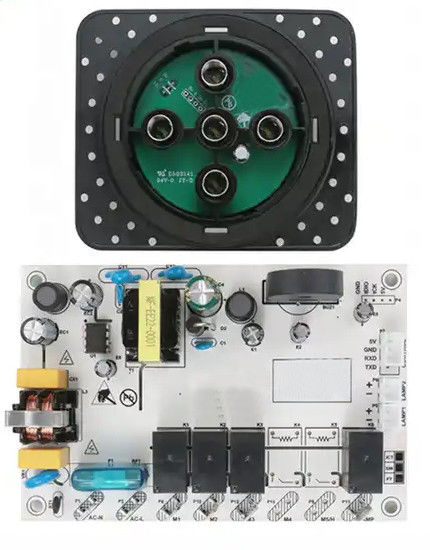

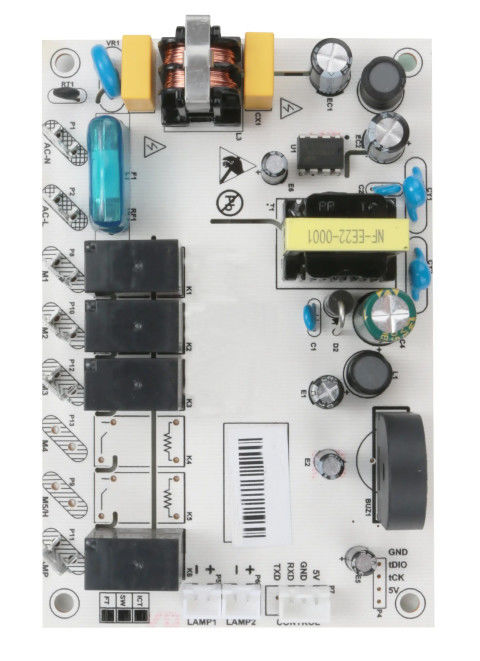

Electronic PCBA Manufacturing PCB Design Kitchen Appliance Range Hood Control Board.

| Description |

Capability |

|

Application

|

Range hood

|

|

Power

|

1250W

|

|

Function

|

Removing Cooking Fumes

|

|

Service

|

OEM/ODM

|

|

Voltage

|

100~250V |

Electronic PCBA Manufacturing refers to the process of manufacturing and assembling a printed circuit board assembly (PCBA) for a kitchen appliance range hood control board. In this case, the PCBA is specifically designed for controlling the functions of a range hood in a kitchen. Here's a description of its features and functionalities:

PCB Design: The PCB design for the range hood control board includes the necessary circuitry to control and manage the various functions of the range hood. It incorporates components such as micro controllers, sensors, switches, display panels, and connectors. The design is specific to the range hood's features and capabilities.

Power Supply and Regulation: The PCB design includes power supply circuitry to convert the incoming AC power to the appropriate voltage levels required for the range hood's operation. It incorporates voltage regulators, filters, and protection mechanisms to ensure a stable and clean power supply to the range hood's components.

Fan Speed Control: The PCB design includes circuitry to control the fan speed of the range hood. It may incorporate switches, buttons, or touch-sensitive controls to select different fan speeds. The PCB manages the motor that drives the fan and ensures smooth and efficient operation.

Lighting Control: The PCB design includes circuitry to control the lighting of the range hood. It may incorporate switches, buttons, or touch-sensitive controls to turn the lights on or off and adjust their brightness. The PCB manages the power supply to the lighting elements, ensuring proper illumination during cooking activities.

User Interface: The PCB design incorporates a user interface, such as an LCD display or LED indicators, to provide information and feedback to the user. It may display the fan speed, lighting status, timer settings, or other relevant information. The user interface allows users to easily interact with and control the range hood's functions.

Control Algorithms: The PCB design may include control algorithms that enable intelligent and efficient operation of the range hood. These algorithms can adjust fan speeds based on cooking activity or air quality, optimize power consumption, and provide advanced features such as auto-shutoff or delayed start.

Safety Features: The PCB design incorporates safety features to ensure the safe operation of the range hood. It may include over current protection, over voltage protection, short circuit protection, and temperature monitoring mechanisms. These protections safeguard the range hood's components and prevent potential hazards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!