Induction Cooker PCB PCBA Assembly manufacturer.

| Description |

Capability |

|

Copper Thickness

|

1oz

|

|

Min. Hole Size

|

0.25mm

|

|

Min. Line Width

|

0.1mm

|

|

Min. Line Spacing

|

0.1mm

|

|

Surface Finishing

|

HASL

|

|

Board Size

|

manufacture

|

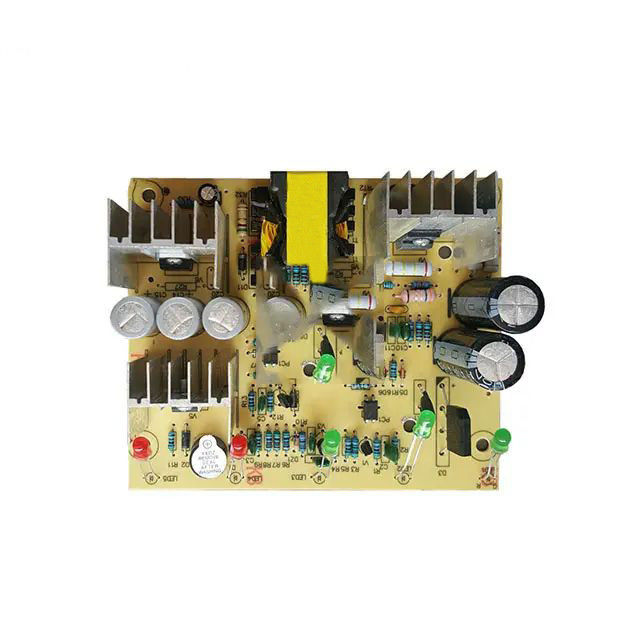

An induction cooker PCB PCBA assembly manufacturer is a company that specializes in the production and assembly of printed circuit board (PCB) assemblies for induction cookers. Here's a description of the manufacturing process and key features involved in producing such PCB assemblies:

PCB Design: The manufacturer begins by creating a PCB design specifically tailored for induction cookers. This design includes the necessary circuitry and components to control the induction heating elements, power supply, user interface, safety features, and any additional functionalities.

PCB Manufacturing: The manufacturer produces the PCB s based on the design specifications. This involves processes such as printing the PCB layout onto a copper-clad board, etching to remove excess copper, drilling holes, and applying solder mask and silkscreen layers. The PCB manufacturing process ensures the precise implementation of the circuit design.

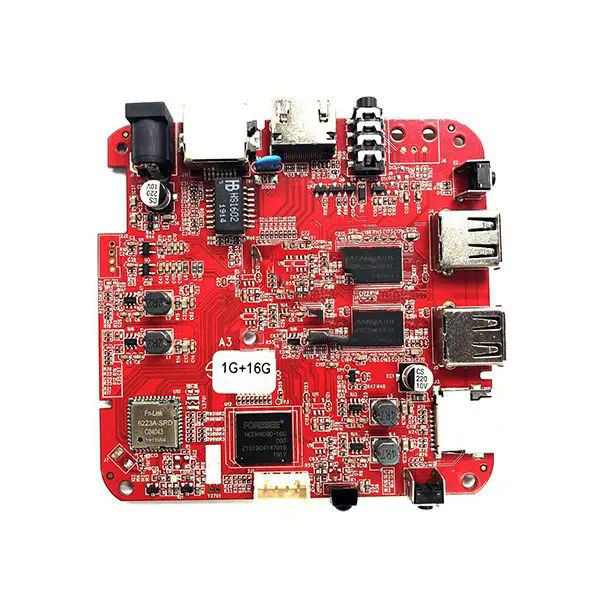

Component Sourcing: The manufacturer sources the required electronic components for the induction cooker PCB assembly. These components include micro controllers, power electronics, capacitors, inductors, resistors, sensors, and other necessary components. The manufacturer ensures that the components are of high quality and meet the specified requirements.

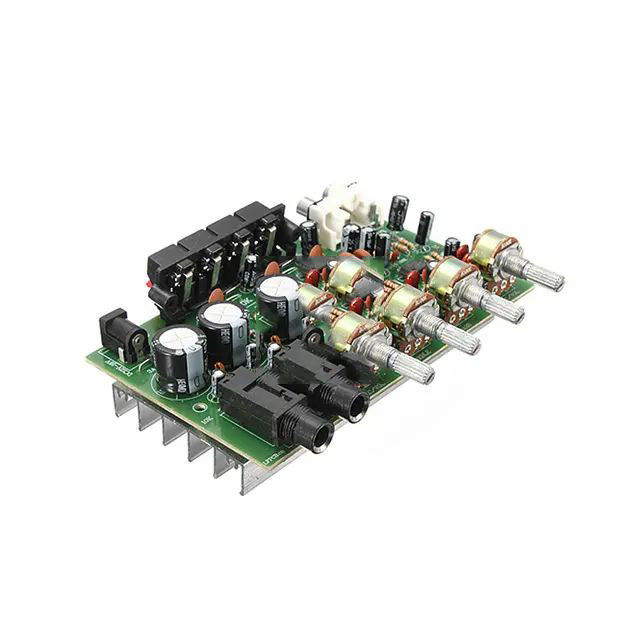

Surface Mount Technology (SMT) Assembly: The manufacturer utilizes SMT assembly techniques to mount the surface-mount components onto the PCB. Automated pick-and-place machines accurately place the components onto the PCB, and solder paste is applied to hold them in position. The PCB is then passed through a reflow oven, where the solder paste is melted, creating strong electrical connections.

Through-Hole Assembly: Some components with through-hole leads may be required for the induction cooker PCB assembly. The manufacturer uses through-hole assembly techniques to mount these components onto the PCB. This may involve manual soldering or automated wave soldering processes.

Safety Features: Induction cookers require various safety features to ensure safe operation. The manufacturer incorporates safety mechanisms into the PCB assembly, such as over current protection, over voltage protection, short circuit protection, temperature monitoring, and other safety features. These protections safeguard the induction cooker and prevent potential hazards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!