Manufacturer's Single-Sided PCB Improved 94v0 Rice Cooker Circuit Board with FR4 Base OSP Surface Finishing.

| Description |

Capability |

|

Material

|

FR-1

|

|

Purpose

|

Electronics

|

|

Packaging

|

Vacuum packaging

|

|

Testing

|

Flying-probe Tester

|

A manufacturer's single-sided PCB refers to a printed circuit board that has circuitry and components mounted on only one side of the board. In this case, the PCB has been specifically designed for an improved 94V0 rice cooker circuit board. Here's a description of the key aspects of this PCB and its manufacturing process, including the use of an FR4 base material and OSP surface finishing:

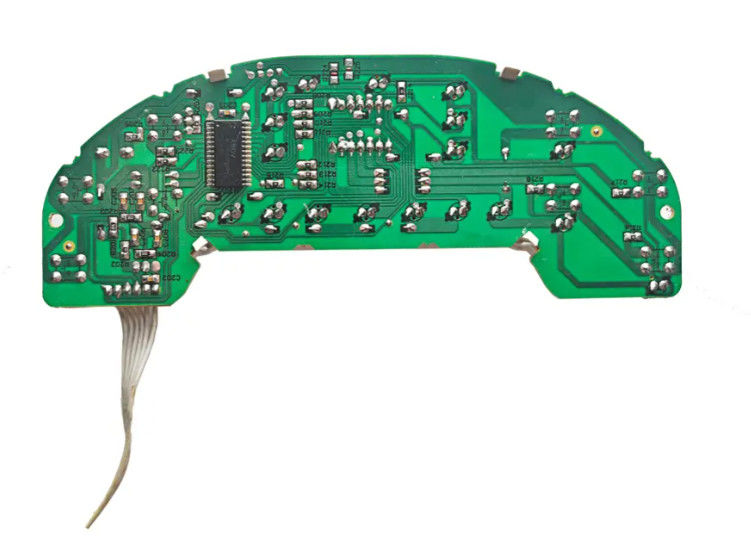

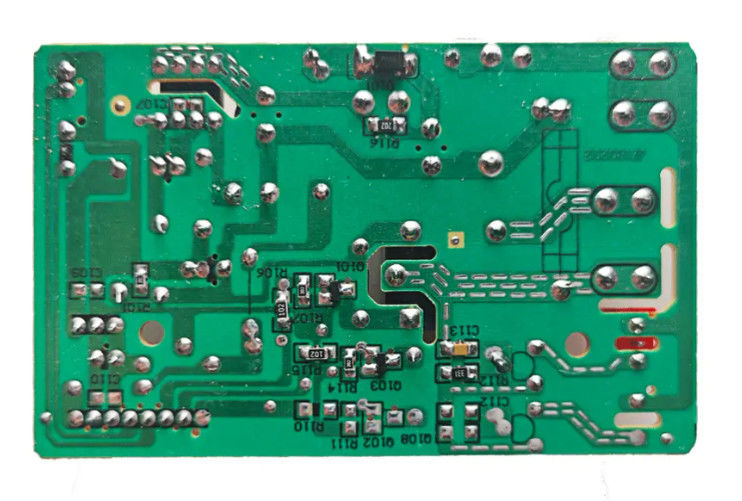

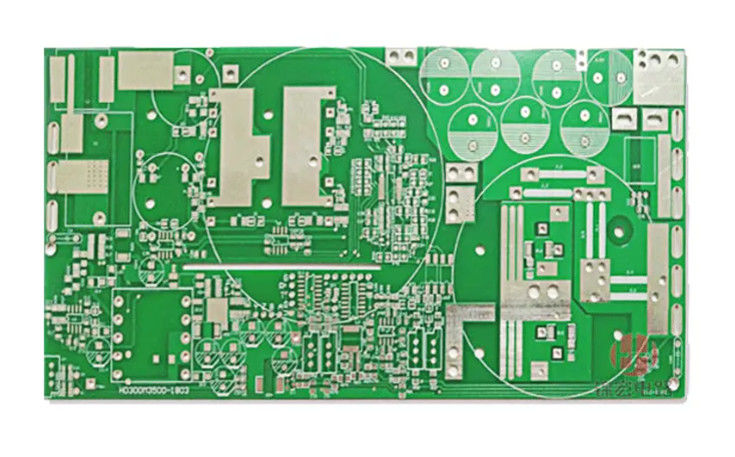

Single-Sided PCB Design: The manufacturer creates a design for the single-sided PCB that meets the specific requirements of the improved 94V0 rice cooker circuit board. The design includes the layout and placement of components, routing of signal traces, power management, temperature control, user interface features, and safety mechanisms necessary for the rice cooker's operation.

FR4 Base Material: The PCB is constructed using FR4, which is a widely used flame-retardant fiberglass epoxy laminate material. FR4 is known for its excellent electrical insulation properties, mechanical strength, and dimensional stability. It provides a stable and reliable base for mounting components and routing circuit traces.

Copper Layer and Etching: A thin layer of copper is applied to the FR4 base material to create the conductive paths for the circuitry. The copper layer is then selectively etched to remove excess copper, leaving behind the desired circuit traces as per the design.

Component Placement: Components such as micro-controllers, capacitors, resistors, sensors, connectors, and other necessary parts are mounted on the single side of the PCB. The placement of components is done in accordance with the design specifications to ensure proper functionality and efficient use of the available space.

Solder Mask: A solder mask layer is applied to the PCB to protect the copper traces and prevent unwanted solder bridges during the assembly process. The solder mask is typically green in color, but it can also be available in other colors.

OSP Surface Finishing: OSP (Organic Solder ability Preservative) is used as the surface finishing for the single-sided PCB. OSP is a thin protective layer applied to the copper traces to prevent oxidation and ensure good solder ability. It provides a flat and uniform surface for soldering components during assembly.

Silkscreen and Legend Printing: The manufacturer may add a silkscreen layer to the PCB, which includes printed component outlines, reference designators, and other markings to assist with component placement and identification. Legend printing may also be added to provide additional information, such as component values or important warnings.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!