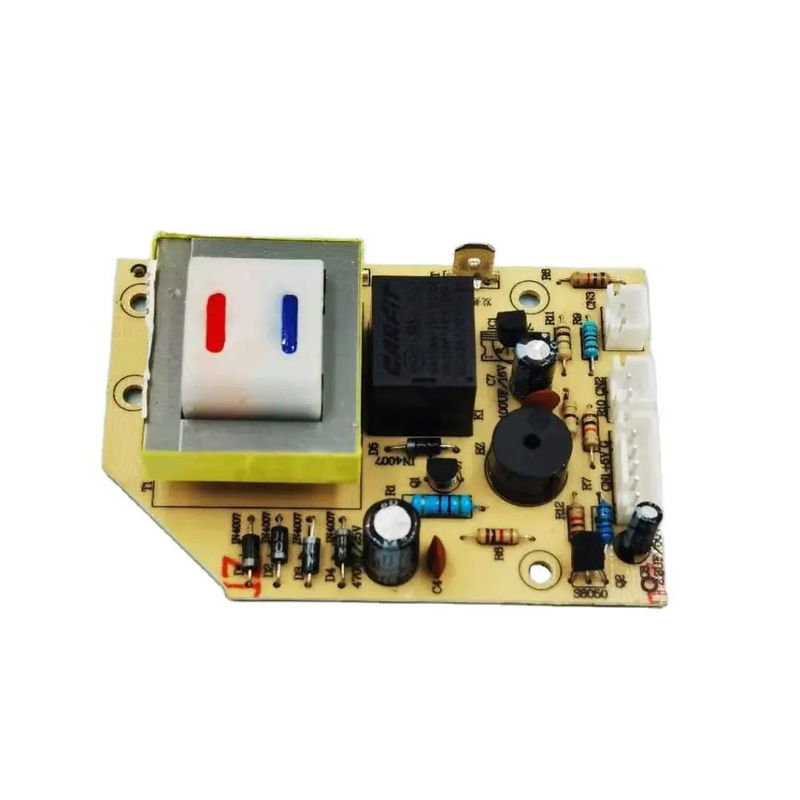

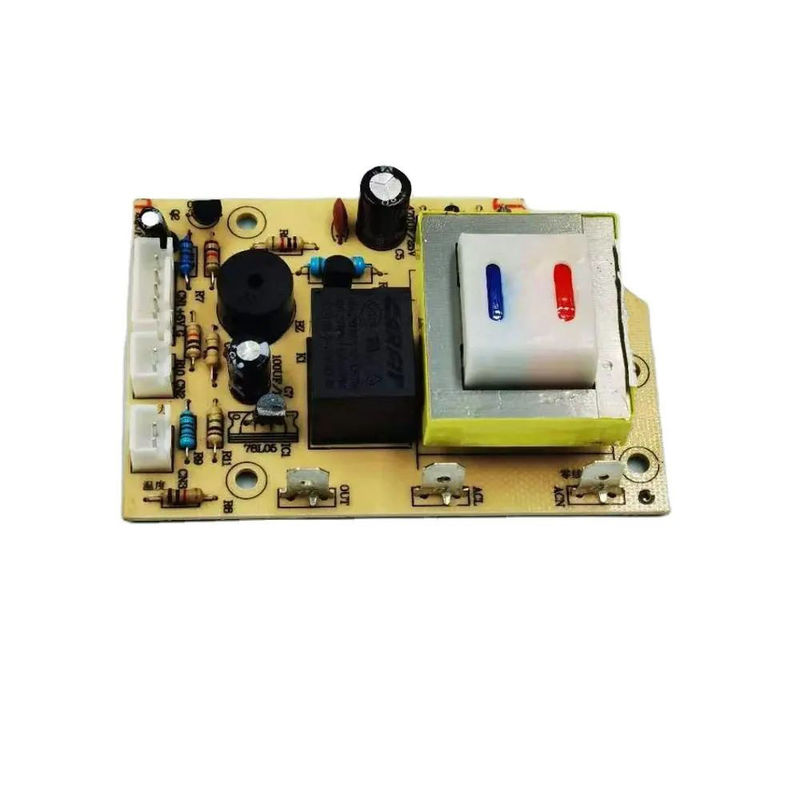

High Quality Rice Cooker Automatic Control Board PCBA Controller Panel Manufacturer.

| Description |

Capability |

|

Type

|

Rice cooker part

|

|

Keyword

|

Universal board circuit board

|

|

Usage

|

Electric Rice cooker

|

A high-quality rice cooker automatic control board PCBA (Printed Circuit Board Assembly) controller panel manufacturer specializes in producing reliable and efficient control boards for rice cookers. Here's a description of the key aspects of a high-quality manufacturer for rice cooker control board PCBA:

Expertise and Experience: A high-quality manufacturer has extensive expertise and experience in designing and manufacturing control boards for rice cookers. They understand the specific requirements and challenges involved in creating a reliable, efficient, and safe control board for rice cooker applications.

Design and Engineering: The manufacturer has a team of skilled designers and engineers who work on the design and development of the control board. They ensure that the design meets the required specifications, including temperature control, cooking modes, timing, safety features, and user interface functionalities.

Component Selection: The manufacturer carefully selects high-quality electronic components for the control board. This includes micro-controllers, sensors, power management ICs, capacitors, resistors, connectors, and other necessary parts. The components are sourced from reputable suppliers to ensure reliability and performance.

PCB Manufacturing: The manufacturer utilizes advanced PCB manufacturing techniques to produce high-quality control boards. This includes precise drilling, copper plating, etching, solder mask application, and silkscreen printing. The use of high-quality materials and stringent manufacturing processes ensures the durability and reliability of the control board.

Surface Mount Technology (SMT) Assembly: The control board assembly is performed using state-of-the-art SMT assembly techniques. Automated pick-and-place machines accurately position the components onto the PCB, and solder paste is applied to create strong electrical connections. The PCB is then passed through a reflow oven to melt the solder paste and form secure solder joints.

Quality Control and Testing: Stringent quality control measures are implemented throughout the manufacturing process. Visual inspections, automated optical inspection (AOI), functional testing, and electrical testing are conducted to ensure the reliability and functionality of the control board. These procedures help identify and rectify any defects or issues.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!