Wireless Mobile Charger PCB Assembly PCB Board Service Manufacturerfor Household.

| Description |

Capability |

|

Number of Layers

|

1 Layer-12layer

|

|

Board Thickness

|

0.2mm-4mm

|

|

Base Material

|

FR4/ROGERS/PET/HDI/CEM/PI

|

|

Testing Service

|

Function Test

|

|

Copper Thickness

|

1/2OZ 1OZ 2OZ 3OZ

|

Wireless mobile charger PCB assembly PCB board service manufacturers for households provide expertise and services related to the manufacturing and assembly of PCBs for wireless mobile chargers. Here's a description of the key aspects of their services:

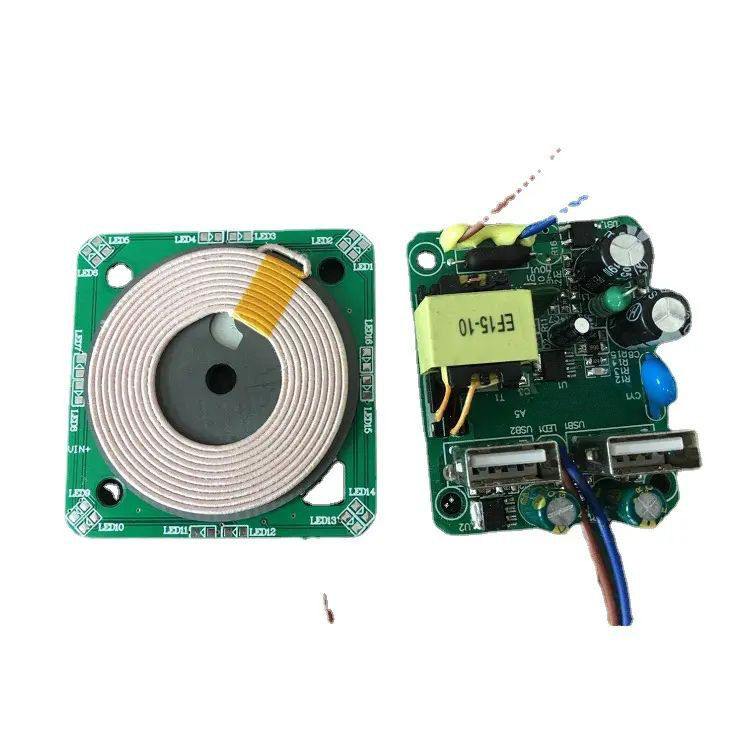

PCB Design and Customization: The service provider assists in designing or customizing the PCB layout for the wireless mobile charger. They consider factors such as the charging technology (e.g., Qi wireless charging), power requirements, and compatibility with various mobile devices. The design is tailored to meet the specific requirements of household use, including size, shape, and functionality.

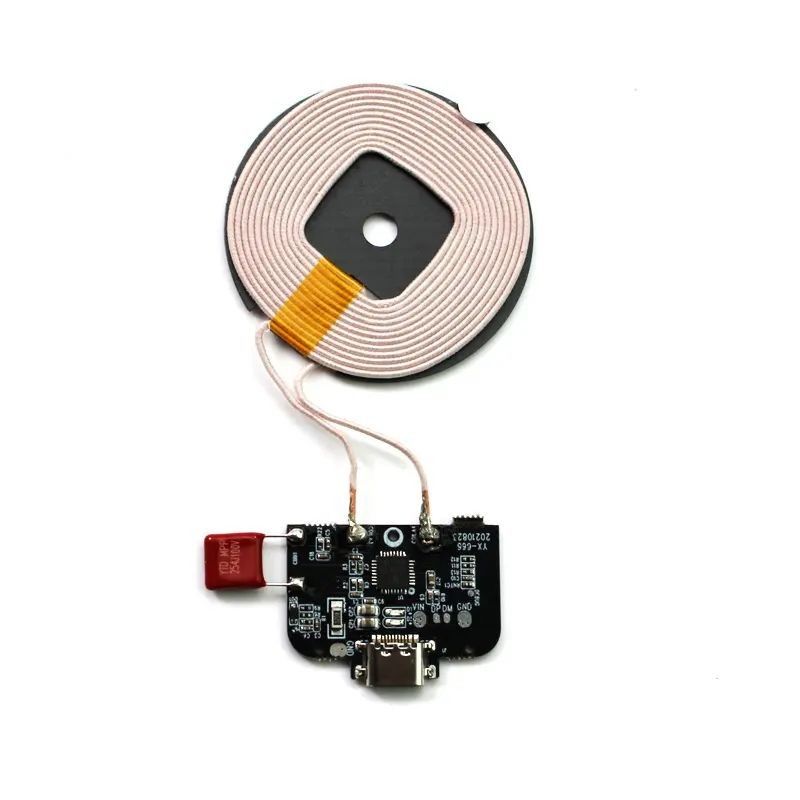

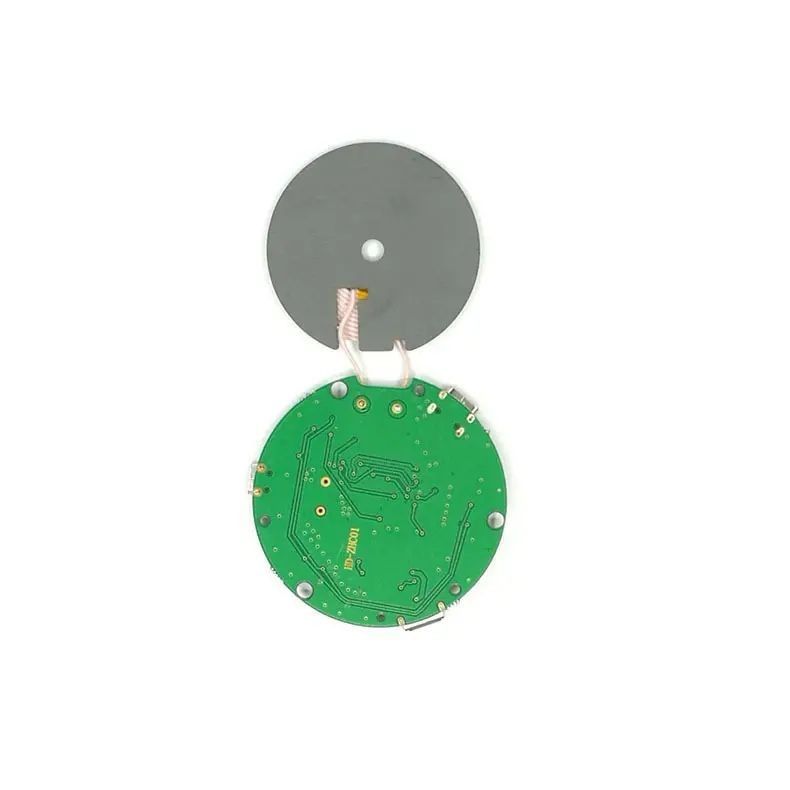

Component Selection and Sourcing: The manufacturers help in selecting suitable electronic components for the wireless mobile charger PCB assembly. This includes components like voltage regulators, wireless charging coils, capacitors, resistors, integrated circuits, and connectors. They source components from reliable suppliers to ensure quality and performance.

PCB Manufacturing: The PCB manufacturing process involves fabricating the circuit board using advanced techniques. This includes applying copper layers, etching to create circuit traces, and applying solder mask and silkscreen layers. The service provider works with reputable PCB manufacturers to ensure high-quality boards that meet the specifications and requirements of wireless mobile chargers.

Surface Mount Technology (SMT) Assembly: The assembly of surface-mount components onto the PCB is carried out using SMT techniques. Automated pick-and-place machines accurately position the components, and solder paste is applied to create strong electrical connections. The PCB is then subjected to reflow soldering to form secure solder joints.

Quality Control and Testing: Stringent quality control measures are implemented during the PCB assembly process. Visual inspections, automated optical inspection (AOI), functional testing, and electrical testing are conducted to ensure the reliability and functionality of the PCB assembly. This helps identify and rectify any defects or issues before the final product is delivered.

Safety Features and Compliance: Wireless mobile charger PCB assemblies for household use incorporate safety features to protect against over current, over voltage, short circuits, and other potential hazards. The service provider ensures compliance with relevant safety standards and regulations to ensure the chargers meet the necessary safety requirements for household use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!