PCBA Household Electrical Appliances Electric Fireplace PCBA Manufacturer.

| Description |

Capability |

|

Service

|

OEM Services Provided

|

|

Base Material

|

FR4/ROGERS/Aluminum/High TG

|

|

Layer

|

1~12 Layers

|

|

Keywords

|

PCBA OEM PCB Assembly

|

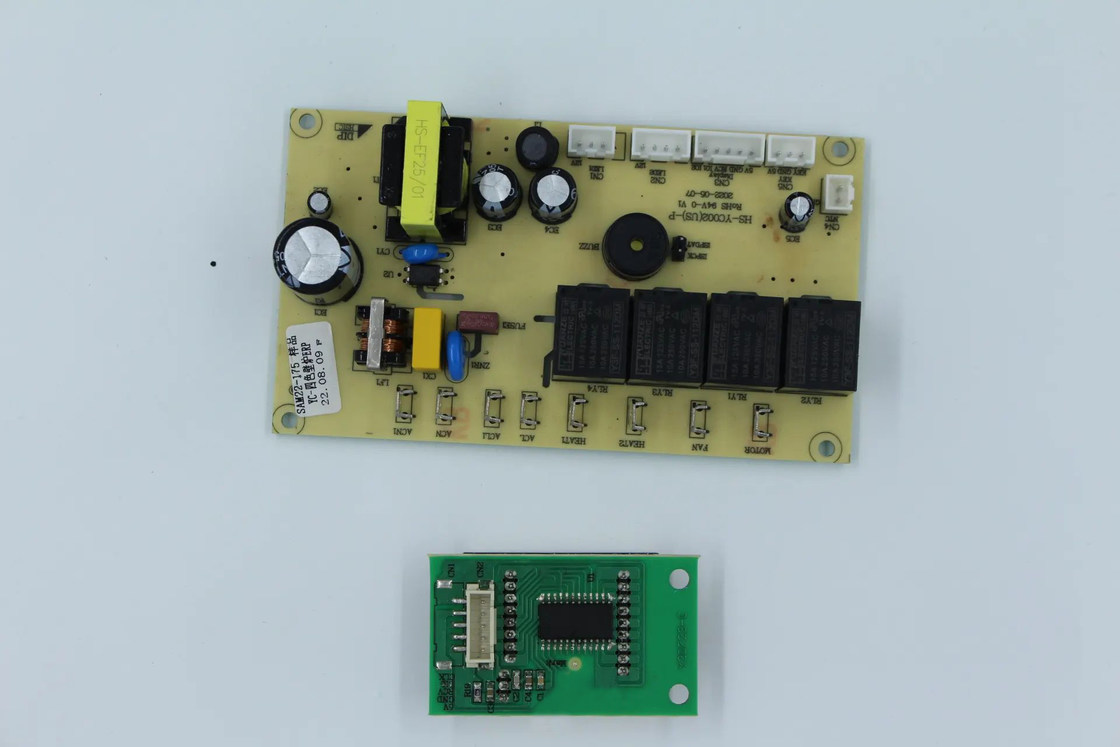

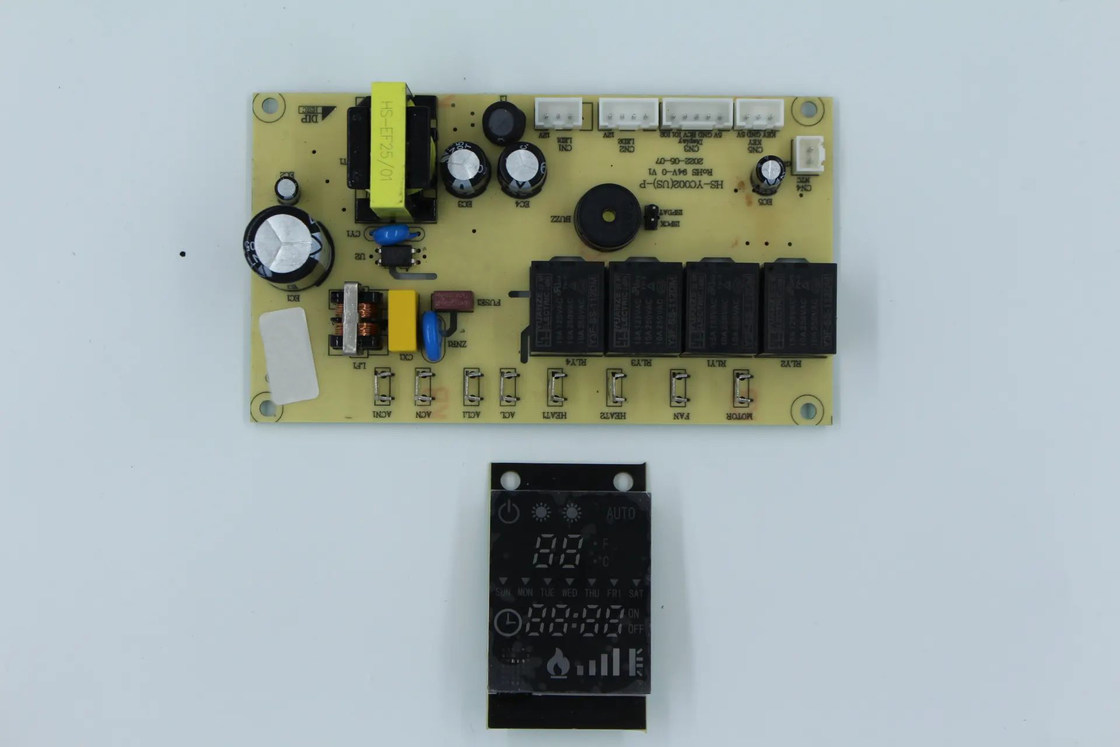

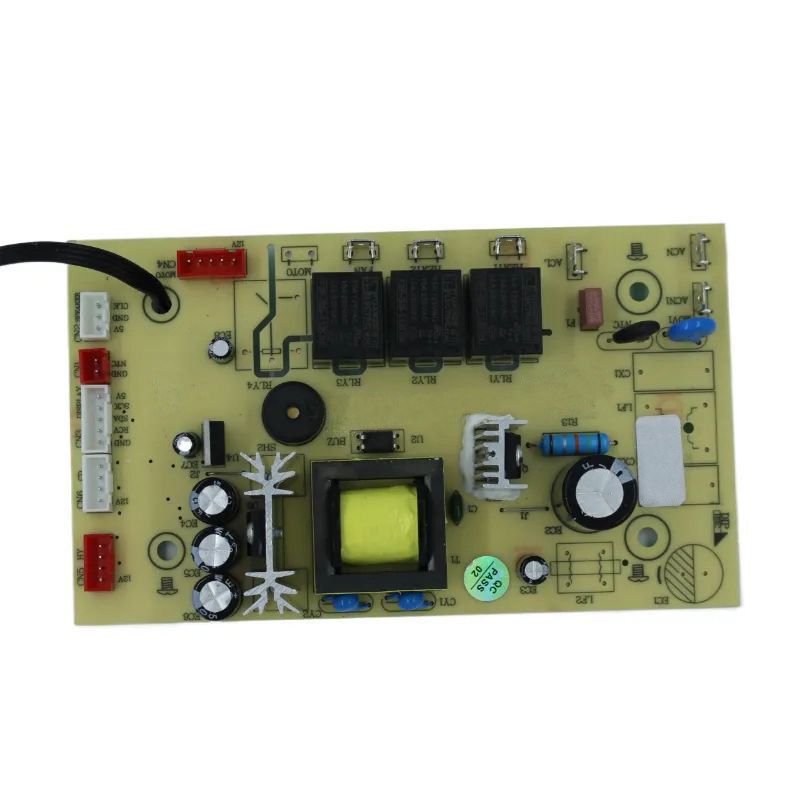

PCBA (Printed Circuit Board Assembly) manufacturers for household electrical appliances, specifically electric fireplaces, provide expertise and services related to the manufacturing and assembly of PCBs for these appliances. Here's a description of the key aspects of their services:

Customized PCB Design: The PCBA manufacturer assists in designing or customizing the PCB layout for electric fireplaces. The design is tailored to meet the specific requirements of the appliance, including the control functions, temperature regulation, flame effect control, user interface, and safety features. The design ensures seamless integration with the overall system of the electric fireplace.

Component Selection and Sourcing: The manufacturer helps in selecting appropriate electronic components for the PCBA. This includes components such as micro-controllers, temperature sensors, power regulators, relays, switches, connectors, and other necessary parts. They source components from reliable suppliers to ensure quality, reliability, and compliance with safety standards.

PCB Manufacturing: The PCB manufacturing process involves fabricating the circuit board using advanced techniques. This includes applying copper layers, etching to create circuit traces, and applying solder mask and silkscreen layers. The manufacturer works with reputable PCB manufacturing facilities to ensure high-quality boards that meet the specifications and requirements of electric fireplaces.

Surface Mount Technology (SMT) Assembly: The assembly of surface-mount components onto the PCB is carried out using SMT techniques. Automated pick-and-place machines accurately position the components, and solder paste is applied to create strong electrical connections. The PCB is then subjected to reflow soldering to form secure solder joints.

Safety Features and Compliance: PCBA s for electric fireplaces incorporate safety features to ensure safe operation. These features may include overheat protection, short circuit protection, flame detection, and mechanisms to prevent electrical hazards. The manufacturer ensures compliance with relevant safety standards and regulations to ensure the electric fireplaces meet necessary safety requirements.

Documentation and Support: Comprehensive documentation, including assembly drawings, bills of materials (BOM), and test reports, is provided by the manufacturer. This documentation aids in future reference, troubleshooting, and maintenance of the electric fireplaces. Additionally, they offer technical support and assistance to address any inquiries or issues related to the PCBA.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!