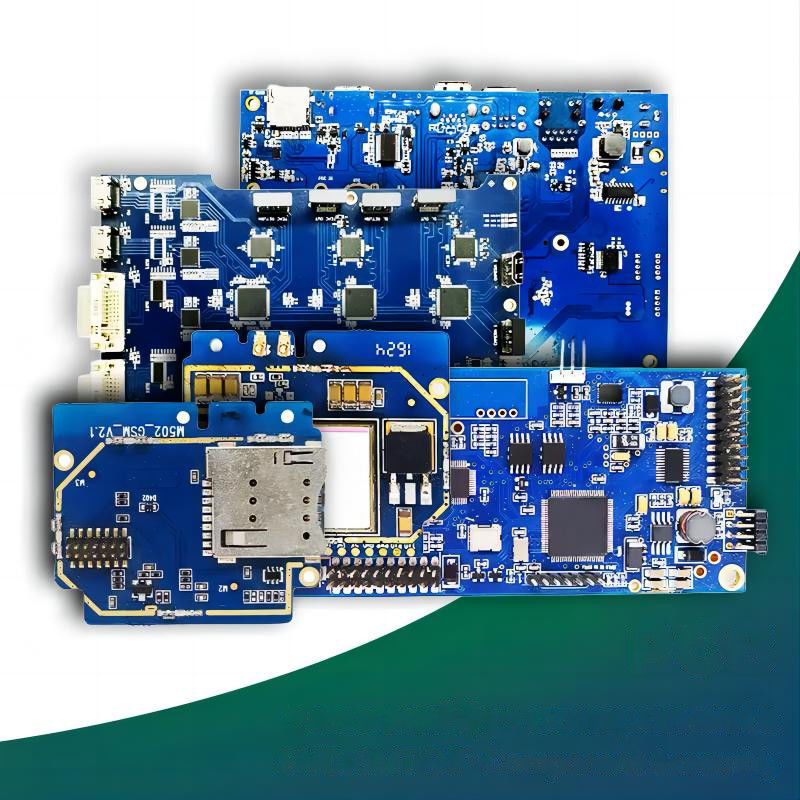

Assembly Electric Iron PCBA Smart Home PCBA PCB Assembly.

| Description |

Capability |

|

Min. Hole Size

|

0.2mm |

|

Min. Line Width

|

4mil |

|

Min. Line Spacing

|

4mil |

|

Surface Finishing

|

Gold Plating |

|

Type

|

Multi-layer PCB |

|

Layers

|

1-28 |

|

Base Material

|

FR4, High TG FR4, High Frequency, Alum, FPC |

|

Copper Thickness

|

1OZ |

|

Min Hole Size

|

0.2mm |

|

Min BGA

|

0.25mm |

|

PCB Standard

|

IPC-II Standard |

|

Function

|

Signal transmission |

The Assembly Electric Iron PCBA and Smart Home PCBA PCB Assembly are two separate electronic assemblies used in different applications. Here's a description of each:

Assembly Electric Iron PCBA: The Assembly Electric Iron PCBA refers to the Printed Circuit Board Assembly used in an electric iron. It is responsible for controlling the heating element, temperature regulation, and other features of the electric iron. The PCBA typically includes the following components:

Micro controller or microprocessor: Manages the control and regulation of the electric iron's temperature and other functionalities.

Power supply circuitry: Converts the input power source (typically AC) to the appropriate voltage and current levels required for the heating element and other electronic components.

Temperature sensor: Monitors the temperature of the heating element and provides feedback to the micro controller for temperature regulation.

Heating element driver: Controls the power delivered to the heating element based on the temperature set by the user.

User interface components: This may include buttons, switches, and an LCD or LED display for adjusting temperature settings and displaying other information.

The Assembly Electric Iron PCBA undergoes rigorous testing to ensure proper functionality, safety, and performance.

Smart Home PCBA: The Smart Home PCBA refers to the Printed Circuit Board Assembly used in smart home devices. It is designed to provide intelligent control and connectivity features for various smart home applications. The PCBA typically includes the following components:

Micro controller or microprocessor: Manages the control and communication functions of the smart home device. It may be equipped with wireless capabilities (such as Wi-Fi or Bluetooth) to connect with smart home ecosystems or smartphone applications.

Sensors: Depending on the specific smart home application, the PCBA may include various sensors like temperature, humidity, motion, or light sensors.

Communication modules: These modules enable the smart home device to connect and communicate with other devices or a central smart home hub.

Power management circuitry: Controls the power supply and distribution within the smart home device.

User interface components: This may include buttons, touchscreens, or voice control interfaces for user interaction. The Smart Home PCBA is designed to enable automation, remote control, and integration with other smart devices and platforms in a smart home setup. It is tested to ensure proper functionality, compatibility, and security.

Electric Iron PCBA and Smart Home PCBA PCB Assembly are two distinct electronic assemblies with different purposes. The Assembly Electric Iron PCBA controls the heating element and temperature regulation in an electric iron, while the Smart Home PCBA provides intelligent control and connectivity features for various smart home applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!